FLAT GASKETS

At CTG, our specialty is custom applications. We use the most current technology to eliminate the need for expensive dies. We know that when you have a custom application, you are going to need it fast, so we have the automated machinery, the materials inventory, and the expertise to get it done.

The type of gasket you need but cannot find, is the type of gasket that we make every day at CTG.

Safety Data Sheet PDFRequest QuoteApplications

- High temperatures

- High and low pressures

- Surfaces with a relatively large tolerance gap

- Static systems

- Corrosive environments

Benefits

- A simple, inexpensive, and effective way to prevent leakage

- through two surfaces in contact

- Easy to make in a wide variety of forms and sizes

- Readily fabricated from custom materials to meet the exact needs of the application

- Able to manufacture just a few or several thousand

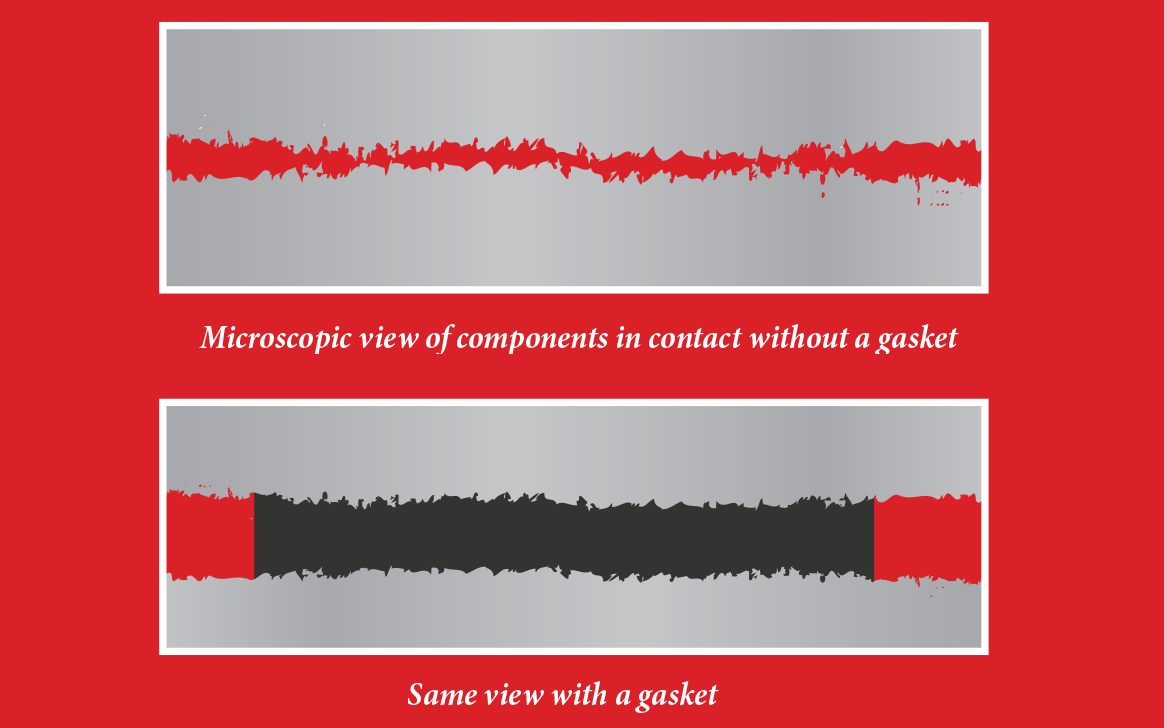

Design Principle

Gaskets are designed to prevent fluid leakage through the microscopic spaces that exist between two surfaces nominally in contact. When the gasket is compressed between the two surfaces, the gap is sealed.

The material that is best suited for a particular gasket depends on the temperature, pressure, fluid, and chemicals to which the gasket will be exposed during operation. Our experienced engineers will help you select exactly the right material for your situation, and manufacture the gasket to your specifications that same day.

Request a quote

For emergency needs, 24/7 delivery is also availableThe optimum material to use for any particular gasket depends on various factors such as the temperature range over which the gasket will be operating and any chemicals or vapors that it will encounter. If you are unsure what material would work best in your application, tell us what conditions your gasket will experience, and we will help you determine the optimum material.

The following list represents just a few of the materials that are often used to construct gaskets. If the material you need to use is not on this list, we make gaskets from a wide range of materials.

- Acetate

- Black rubber, cloth-inserted

- Black rubber sponge (open cell)

- Buna-N (50, 60, and 90 durometer)

- Buna-N (50-65 durometer, white)

- Buna-N, nylon-inserted

- Butyl

- Chipboard

- Cork

- Cork and Buna-N

- Cork and neoprene

- Cork and synthetic rubber, adhesive-backed

- EPDM

- Felt

- Fiber and cork

- Fiberglass cloth

- Flexible graphite (GHR, GHE)

- Gum rubber

- GRI/Durlon 8500

- GRI/Durlon 9000

- Hypalon

- Koroseal

- Leather

- Neoprene, 40 and 60 durometer

- Neoprene, cloth-inserted

- Neoprene sponge (closed cell)

- Neoprene tank gasket

- Nylon

- Plant (vegetable) fiber

- Polyethylene

- Red rubber

- Rubber matting

- Silicone, 50 and 70 durometer

- Silicone sponge

- PTFE

- PTFE, glass filled

- Urethane

- Viton®

- Vulcanized fiber-bone (red)

24/7 Emergency Delivery Available

24/7 Emergency Delivery Available