T-SEALS

T-seals are used when an O-ring’s outstanding ability to seal over a wide range of pressures and temperatures is required, but an improved solution with greater resistance to extrusion and twisting is also necessary.

T-seals fit into existing O-ring grooves, so no re-machining or redesign of the existing hardware is involved. As a result, field changes and new equipment manufacturing are both made easier.

CTG’s experienced engineers will custom tailor T-seals to your exact requirements, and manufacture 1 or 1,000 seals to your specifications that same day.

O-Rings PDFRequest QuoteDesign Principle

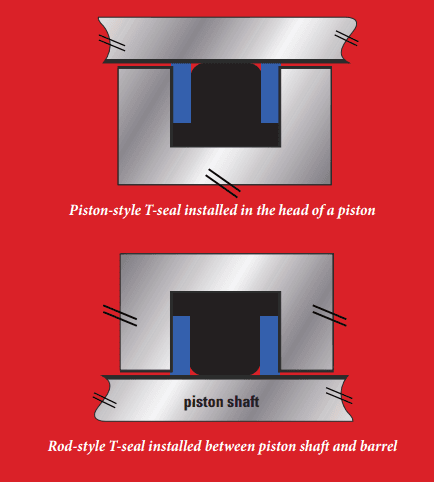

A T-seal consists of a ring of elastomeric material that has a T-shaped cross section, and two bands of relatively rigid material that belong on either side of the elastomer ring. The ring acts as the sealing component of the unit, and the two rigid bands act as backup rings that prevent extrusion of the elastomer ring into the extrusion gap of the gland.

As a bonus, the backup rings in a T-seal serve an additional purpose: they firmly hold the sealing component to the floor of the gland, preventing the seal from twisting. As a result, T-seals are practically immune to spiral failure.

For maximum seal longevity, the seal must be constructed from the correct elastomer for the particular application. CTG can build seals from elastomers that tolerate high or low temperatures, high or low pressures, dynamic applications, and corrosive environments. If you are unsure which material would be best, ask us—our engineers will select the right material for your situation.

Applications

- Oilfield hydraulic pistons and rods

- Other static or reciprocating applications

- High or low temperatures

- High or low pressures

- Corrosive environments

Benefits

- Fabricated from custom materials to meet the exact needs of the application.

- Directly replaces an O-ring in the same size gland (No re-machining or redesign required)

- Highly resistant to spiral (twisting) failure

- Highly resistant to extrusion

- Gives a tight, leak-proof seal

- Usable with comparatively large extrusion gaps

- Provides prolonged service

- Requires minimum maintenance

Request a quote

For emergency needs, 24/7 delivery is also availableThe following table details the materials that are commonly used to construct O-ring energized seals.

| Material | Temperature Range(°F)* | Comments and Typical Uses |

| Nitrile (Buna-N, NBR) | -20 to 212 | Highly resistant to abrasion and tearing. Nitrile is the most commonly used elastomer for sealing applications, and it is the material of choice for petroleum applications. |

| Hydrogenated nitrile (HNBR) | -20 to 300 | Compared to nitrile, HNBR has better chemical resistance, better heat resistance, and better resistance to seal extrusion. |

|

Ethylene-propylene (EPDM)

|

-60 to 250 | Very resistant to ozone. |

|

Neoprene

|

-40 to 250 | Resists both weathering and exposure to petroleum oils |

| Butyl (isobutylene, IIR) | -50 to 250 | Extremely low gas permeability; resists a diverse range of chemicals. Useful in applications requiring an air-tight seal. |

| Viton® (fluorocarbon, fluoroelastomer) | -15 to 400 | Better resistance to chemicals and high temperatures than most other elastomers. |

| Silicone (VMQ, PVMQ) | -150 to 400 | Excellent tolerance for temperature extremes, and high resistance to compression set. |

| Fluorosilicone (FVMQ, FK) | -75 to 400 | Tolerant to temperature extremes, and resists degradation by fuel and oils. Primarily used where resistance to hot, dry conditions is required. |

| FFKM (perfluoroelastomer) | -15 to 600 | Highly resistant to many chemicals, and outstanding resistance to high temperatures |

Backup Ring Material

| PEEK | -100 to 550 | A high-modulus material with excellent thermal and mechanical properties.. |

| PPS | -40 to 425R | Can be machined to tight tolerances. Has the broadest resistance tochemicals of any advanced engineering plastic. Is inert to steam, strongbases, fuels, and acid. Has no known solvent below 392°F and does notabsorb moisture. |

Nylon |

-20 to 210 |

Tough, and resistant to abrasion. Good resistance to hydrocarbons,

aromatic and aliphatic solvents, common automotive oils and lubricants,

and refrigerants. Items fabricated with nylon can be used without lubrication.

|

PTFE |

-400 to 450 |

Highly resistant to many chemicals, and can function over a very wide

temperature range. Also resists weathering.

|

24/7 Emergency Delivery Available

24/7 Emergency Delivery Available