Backup Rings (BUR)

Backup rings are made of a relatively hard material. They are installed in the gland between an O-ring (or an X-ring) and the low-pressure side of the seal to prevent the O-ring from being forced into the extrusion gap.

Backup rings are commonly used when an application operates under pressures exceeding 1,500 psig, or when components are designed with a relatively large extrusion gap through the gland. Backup rings enable slightly lower machining tolerances and increase the seal performance and seal life.

CTG supplies backup rings in different styles, including solid rings, split rings, and double (spiral) rings. We manufacture backup rings in any size, and in your choice of material.

Safety Data Sheet PDFRequest QuoteApplications

- High temperature

- High pressure

- Glands with a relatively large tolerance gap

- Static or dynamic systems

- Corrosive environments

Benefits

- A simple, inexpensive, and effective way to prevent seal failure by extrusion

- A wide variety of forms and sizes

- Readily fabricated from custom materials to meet the exact needs of the application

- Gland components can be machined to lower tolerances

- Reduces need for seal maintenance

Design Principle

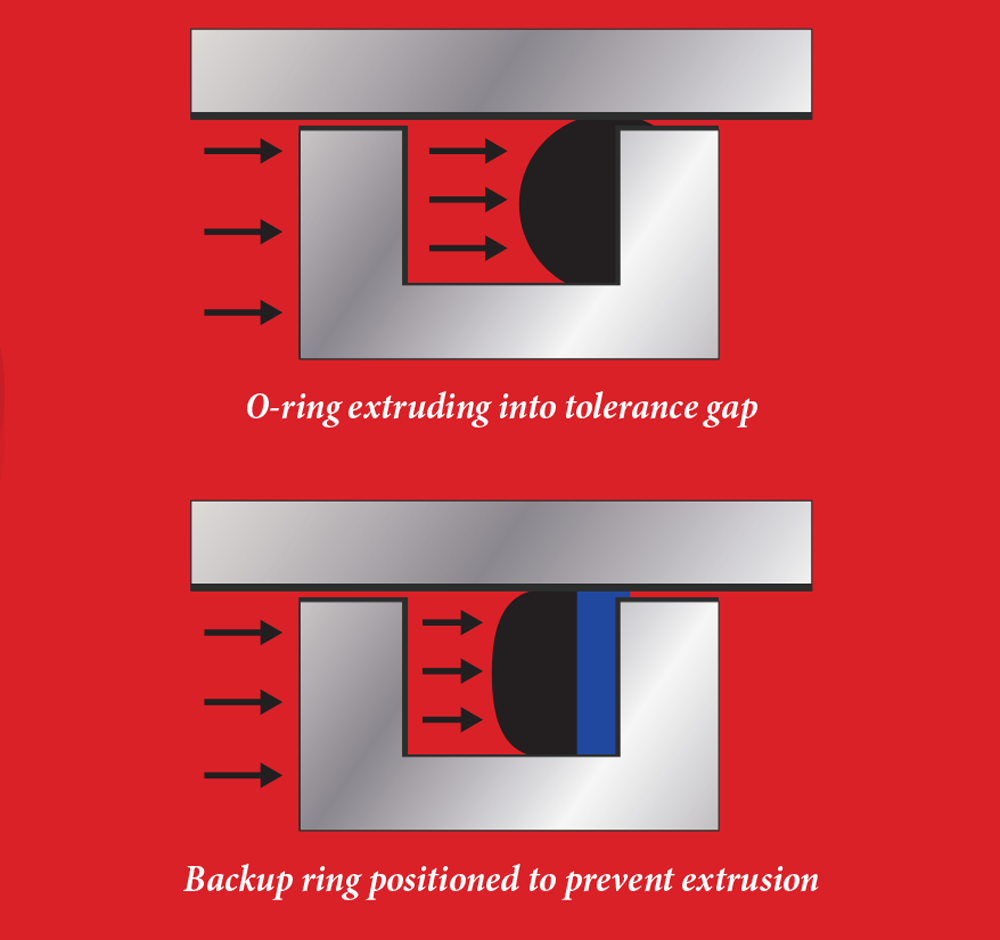

When a mechanical system operates under mild conditions, an O-ring (or X-ring) in the system is compressed against the low-pressure side of its O-ring groove (gland) to form a seal. As temperature or pressure increases, the O-ring deforms increasingly out of round; and, if the temperature or pressure becomes sufficiently high, the O-ring starts to extrude into the tolerance gap between the two gland components. After this process of extrusion begins, the O-ring quickly erodes, and the seal might then fail.

A backup ring is designed to be installed in the gland on the low-pressure side of the O-ring, between the O-ring and the gland wall. During operation, the O-ring is compressed against the backup ring instead of the gland wall, and cannot seep into the tolerance gap because the backup ring completely closes the gap between the two gland components.

Request a quote

For emergency needs, 24/7 delivery is also availableThe following table details the materials that are commonly used to construct backup rings. However, backup rings can be made of any reasonably rigid material. Just let us know the dimensions of the backup ring that you need and the material, and then we will have your backup rings ready within a day

| Material | Temperature Range(°F)* | Comments and Typical Uses |

| Nitrile (Buna-N, NBR) | -20 to 212 | Highly resistant to abrasion and tearing. Nitrile is the most commonly used elastomer for sealing applications, and it is the material of choice for petroleum applications. |

| Hydrogenated nitrile (HNBR) | -20 to 300 | Compared to nitrile, HNBR has better chemical resistance, better heat resistance, and better resistance to seal extrusion. |

| Viton® (fluorocarbon, fluoroelastomer) | -15 to 400 | Better resistance to chemicals and high temperatures than most other elastomers. |

| PEEK | -100 to 550 | A high-modulus material with excellent thermal and mechanical properties. |

| PPS | -40 to 425 | Has the broadest resistance to chemicals of any advanced engineering plastic. Is inert to steam, strong bases, fuels, and acids; has no known solvent below 392°F. Does not absorb moisture. Can be machined to tight tolerances. |

| Nylon | -20 to 210 | Tough, and resistant to abrasion. Good resistance to hydrocarbons, aromatic and aliphatic solvents, common automotive oils and lubricants, and refrigerants. Its low coefficient of friction enables items fabricated with nylon to be used without lubrication. |

| PTFE | -400 to 450 | Highly resistant to many chemicals, and can function over a very wide temperature range. Also resists weathering. |

*Temperature ranges given here are approximate; the values relevant to any particular situation depend upon the application. If in doubt, ask us—we will help you design an

O-ring energized seal to meet the temperature tolerance needs of your system.

24/7 Emergency Delivery Available

24/7 Emergency Delivery Available