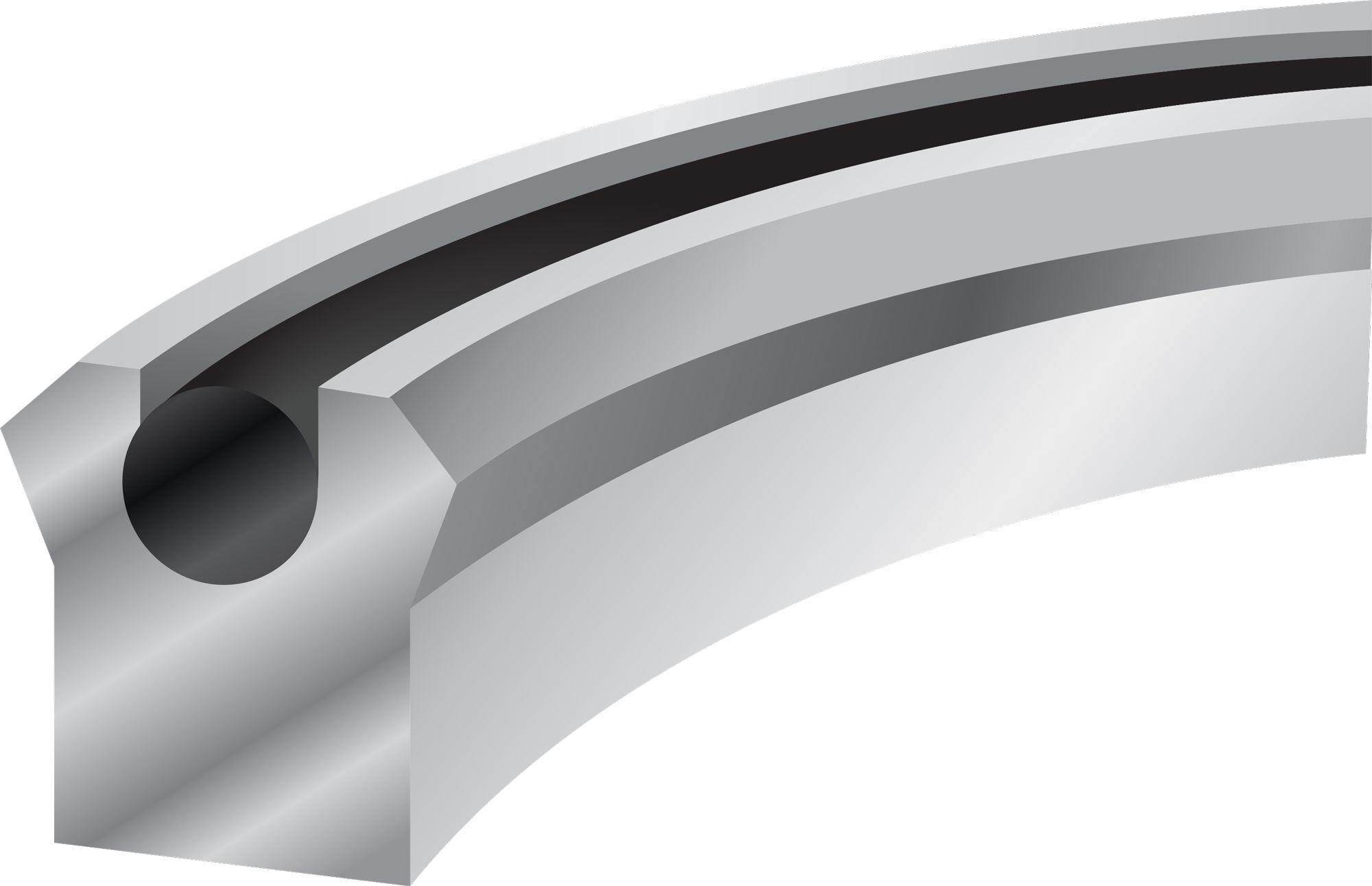

O-RING ENERGIZED SEALS

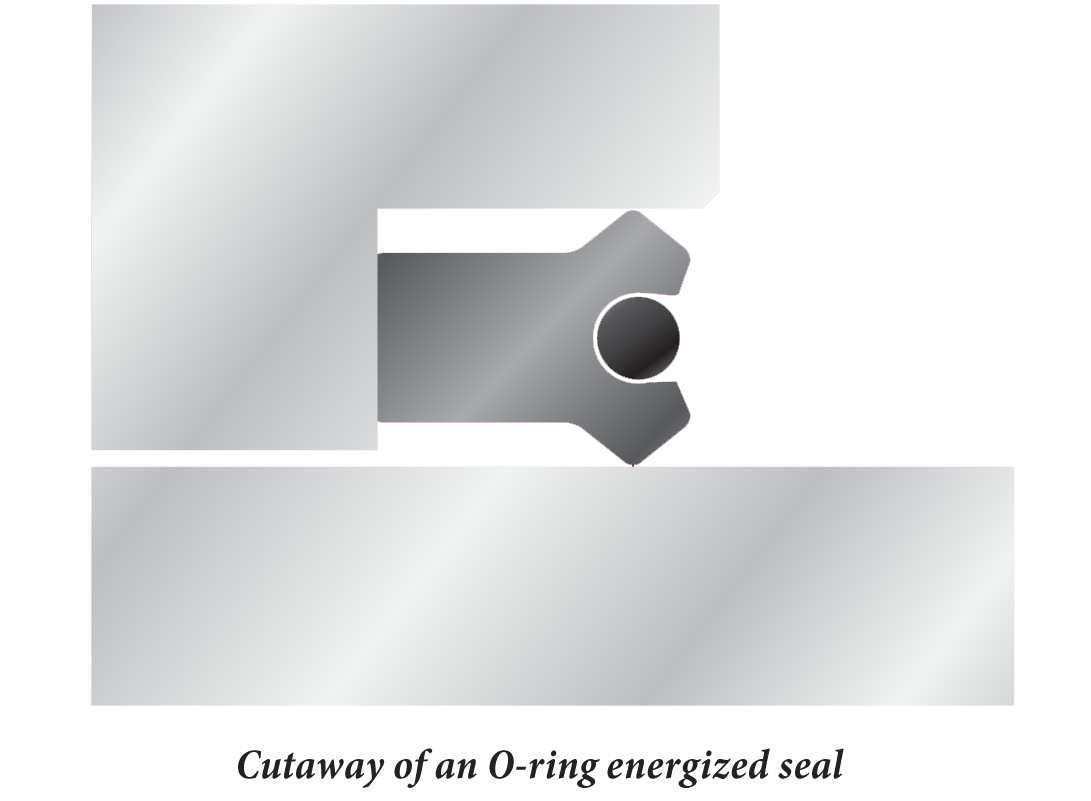

An O-ring energized seal consists of a lip seal in combination with an O-ring. This type of seal is the optimum sealing choice for static or low-speed applications and for vacuum or high-pressure applications. These radial seals can be used in either a rod or piston style application.

The seals can be designed to provide scraping/wiping actions if needed and can be designed for pressures up to 15 ksi.

CTG’s experienced engineers will custom tailor a seal to fit your exact requirements, and manufacture 1 or 1,000 seals to your specifications that same day.

Safety Data Sheet PDFRequest QuoteApplications

- High or low temperatures

- Any pressure (hard vacuum to high pressure)

- Static or low-speed applications

- Corrosive environments

Benefits

- Manufactured from custom materials to meet the exact

- needs of the application

- One-piece design greatly simplifies installation and replacement

- Directly replaces other types of seal in the same size gland

- (no re-machining or redesign required)

- Designed to resist spiral (twisting) failure

- Extremely resistant to extrusion

- Usable with comparatively large extrusion gaps

- Provides prolonged service

- Requires minimum maintenance

Design Principle

Lip seals used alone tend to leak at low pressure because the basic design of a lip seal provides little or no lip loading. When a lip seal is energized by an O-ring, however, sealing at low pressure is greatly improved. As system pressure increases, the seal interface experiences additional force, and a leak-free seal is maintained. For maximum seal longevity, the seal must be constructed from the correct materials for the particular application. CTG can build seals from elastomers that tolerate high or low temperatures, high pressure or high vacuum, and corrosive environments. If you are unsure which material would be best, ask us—we can help you select exactly the right material for your situation.

Request a quote

For emergency needs, 24/7 delivery is also availableThe following table details the materials that are commonly used to construct O-ring energized seals.

| Material | Temperature Range(°F)* | Comments and Typical Uses |

| Nitrile (Buna-N, NBR) | -20 to 212 | Highly resistant to abrasion and tearing. Nitrile is the most commonly used elastomer for sealing applications, and it is the material of choice for petroleum applications. |

| Hydrogenated nitrile (HNBR) | -20 to 300 | Compared to nitrile, HNBR has better chemical resistance, better heat resistance, and better resistance to seal extrusion. |

Ethylene-propylene (EPDM)

|

-60 to 250 | Very resistant to ozone. |

Neoprene

|

-40 to 250 | Resists both weathering and exposure to petroleum oils |

| Butyl (isobutylene, IIR) | -50 to 250 | Extremely low gas permeability; resists a diverse range of chemicals. Useful in applications requiring an air-tight seal. |

| Viton® (fluorocarbon, fluoroelastomer) | -15 to 400 | Better resistance to chemicals and high temperatures than most other elastomers. |

| Silicone (VMQ, PVMQ) | -150 to 400 | Excellent tolerance for temperature extremes, and high resistance to compression set. |

| Fluorosilicone (FVMQ, FK) | -75 to 400 | Tolerant to temperature extremes, and resists degradation by fuel and oils. Primarily used where resistance to hot, dry conditions is required. |

| FFKM (perfluoroelastomer) | -15 to 600 | Highly resistant to many chemicals, and outstanding resistance to high temperatures |

| PTFE | -400 to 450 | Highly resistant to many chemicals, and can function over a very wide temperature range. Also resists weathering. |

*Temperature ranges given here are approximate; the values relevant to any particular situation depend upon the application. If in doubt, ask us—we will help you design an

O-ring energized seal to meet the temperature tolerance needs of your system.

24/7 Emergency Delivery Available

24/7 Emergency Delivery Available